Konkeumshini wokusika we-laserkunezinzuzo zabo, njenge-co2 laser, i-Yag laser njll, kodwa kubonakala sengathi izinzuzo zomshini wokusika i-fiber laser zidlula kude noma yimuphi omunye umshini wokusika we-laser.Ukusika i-fiber laser sekuqalile ukuthola ukunakwa okwengeziwe eminyakeni embalwa edlule.Kodwa-ke, izinzuzo zomshini wokusika i-fiber laser zilethe ukunethezeka okuningi kubakhiqizi abasebenza ngensimbi emhlabeni jikelele.Ngokuthuthuka okusheshayo komshini wokusika i-fiber laser, ingakwazi ukuzivumelanisa kalula futhi ngaphandle komthungo kuhlelo olubanzi lwezicelo ezimbonini ezahlukahlukene.

Umshini wokusika we-fiber laser unezinzuzo eziningana.Okokuqala, Umshini wokusika i-fiber laser ungasebenza ngamandla amakhulu nokusebenza kahle okuphezulu futhi ulungele izinhlobo eziningi zezinqubo zokusika.

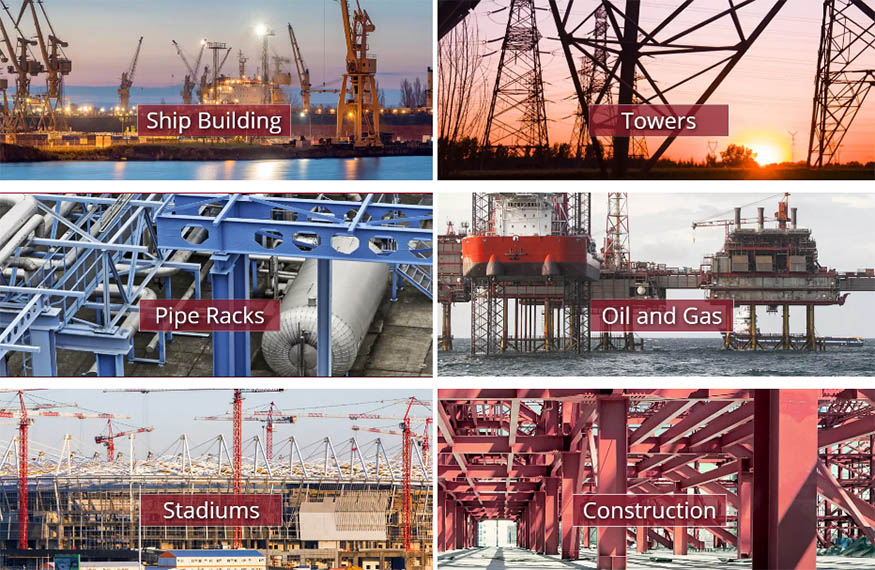

Umshini wokusika i-fiber laser usetshenziswa kabanzi ekucubunguleni okubanzi embonini yeshidi lensimbi ngenxa yezinzuzo zomphumela omuhle kakhulu wokusika, isivinini sokusika esisebenzayo, izindleko eziphansi zokucubungula, kanye nezindleko zokunakekela.Sekuphenduke ucezu lwemishini yokusika ebaluleke kakhulu embonini yensimbi.Izizathu zokuthi kungani imishini yokusika i-fiber laser idumile emakethe yomshini wokusika insimbi ikakhulukazi ngenxa yalezi zizathu ezilandelayo.

Ukuvumelana nezimo okuphezulu

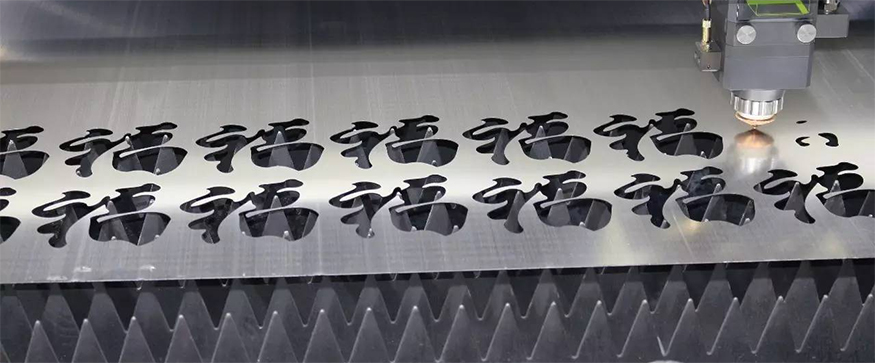

Lapho ucubungula amashidi ensimbi amancane, umshini wokusika i-fiber laser unokuguquguquka okuphezulu ukuze uqaphele ukucubungula okuguquguqukayo.Ingakwazi ukucubungula ngaphandle kokucutshungulwa kwesibili okulandelayo futhi ifaneleka kakhulu ukukhiqizwa okukhulu.Isimiso sokusebenza se-fiber sheet metal laser cutter siwukukhanyisa isigxobo se-laser esinamandla amakhulu kucwecwe lokusebenza lwensimbi ukuze ingxenye ifudunyezwe futhi incibilike.Bese usebenzisa igesi ephezulu yokucindezela ukuze ukhiphe i-slag ukuze uqedele ukusika, ngakho-ke ngeke kube khona ama-burrs nezimo zokupholisha kabusha.

Ukunemba Okuphezulu

I-fiber laser cutting machine beam igxile endaweni encane enobubanzi obungaba ngu-0.1mm.Ukusika kunembile kakhulu futhi kuyahambisana nemvelo futhi.

Inqubo yokusika i-fiber laser yamukela uhlelo lokulawula oluzenzakalelayo ngokugcwele, olusebenzisa ukucubungula okungathinteki ukuze kuqinisekiswe ukuthi impahla ayilinyazwa ukucindezela komshini futhi ngeke ilimaze izingcezu zensimbi zeshidi.

Ezomnotho

Enqubweni yokusika yendabuko, ukusika kwe-workpiece yensimbi yeshidi ngokuyisisekelo kwenziwa ngokuvala.Lapho umkhiqizo omusha noma izimo ezihlukene zensimbi yensimbi ishintshwa, isikhunta sidinga ukushintshwa, okwandisa izindleko ngokungabonakali.Ngaphezu kwalokho, akusizi ukwethula umkhiqizo kusenesikhathi ukuze kwakhiwe ukuncintisana.

Noma kunjalo, i-umshini wokusika we-fiber laserinomjikelezo omfushane wokucubungula wokusika.Ukusika nokucutshungulwa kwezingcezu kungenziwa kalula ngokungeniswa ohlelweni lokulawula izimboni zemishini ngokusebenzisa inguqulo ye-elekthronikhi yomdwebo.Kulokhu, umshini wokusika i-fiber laser unciphise kakhulu umjikelezo wokukhiqiza.Ezinkampanini eziningi, ukufinyeza umjikelezo wokukhiqiza kusho ukuthuthukisa ukuncintisana kwenkampani.Kuyasiza futhi ekulawuleni izindleko futhi kungakhuphula inani lezomnotho.

Imishini yokusika i-fiber laser idlala indima ebalulekile ekucubunguleni insimbi yeshidi.Futhi abakhiqizi abaningi beshidi bensimbi bazokhetha imishini yokusika i-fiber laser ukuze banqume izingcezu zensimbi yeshidi esikhundleni se-plasma noma i-co2 laser cutting.

Phakathi kwabakhiqizi abaningi bensimbi yokusika i-laser, umshini wokusika i-KNOPPO fiber laser udumile emakethe.Ngokuhamba kweminyaka yentuthuko, i-KNOPPO inamandla okukhiqiza wonyaka wemishini yokusika i-fiber laser engu-3000.Umshini wokusika i-fiber laser we-KNOPPO usetshenziswa kabanzi emishinini yokunemba, izingxenye zezimoto, ikhishi nehardware yokugezela, i-elekthronikhi nekagesi, nezinye izimboni eziningi.

Isikhathi sokuthumela: May-21-2021