Ubuchwepheshe bokusika i-Laser ubuchwepheshe obuphezulu bobuchwepheshe obuphelele, obuxube i-optical, isayensi yezinto zokwakha kanye nobunjiniyela, ukukhiqizwa kwemishini, ubuchwepheshe bokulawula izinombolo kanye nobuchwepheshe be-elekthronikhi kanye nezinye iziyalo, njengamanje, kuyindawo eshisayo yokukhathazeka okuvamile kwesayensi nobuchwepheshe kanye nezimboni. imibuthano, kokubili ekhaya naphesheya.Iminyaka engaphezu kwengu-50, ukucubungula kwe-laser nokusetshenziswa okuthuthukayo ngokushesha, kuhlangene neziyalo eziningi zakha inani lesicelo esifakiwe, kanye nobuchwepheshe bokucubungula okuyinhloko be-laser buhlanganisa: ukusika kwe-laser, ukushiswa kwe-laser, ukumaka nge-laser, ukubhola nge-laser, ukwelashwa kokushisa kwe-Laser, i-laser. prototyping ngokushesha, laser enamathela nokunye.

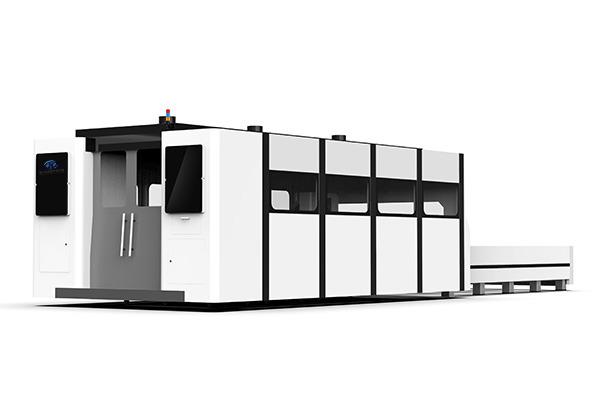

Ubuchwepheshe bokusika i-laser wukusetshenziswa okuyinhloko kobuchwepheshe be-laser embonini.Isheshisa ukuguqulwa kwemboni yokucubungula yendabuko futhi inikeza izindlela ezintsha zokucutshungulwa kwezimboni zesimanje.Sekuyiyona ndlela esetshenziswa kabanzi yokucubungula i-laser emkhakheni wokucubungula izimboni.Njengamanje, ubuchwepheshe bokusika i-laser busetshenziswe kabanzi ekukhiqizeni imishini, ukwakhiwa kwebhuloho, ukucutshungulwa kwensimbi yeshidi, ukukhiqiza umkhumbi nezimoto, imboni kagesi neye-elekthronikhi, izindiza kanye ne-aerospace kanye nezinye izimboni zezinsika zomnotho kazwelonke.Ngokuqhubeka okuqhubekayo kwesayensi nobuchwepheshe kanye nokusetshenziswa, ubuchwepheshe bokusika i-laser buzoqhubekela phambili kwezinye izindawo.

Eminyakeni yamuva, ubuchwepheshe bokucubungula i-laser buthuthuka ngokushesha okukhulu.Ukusetshenziswa kwayo kuya ngokuya kuba kabanzi.ngakho-ke i-laser yaziwa ngokuthi "ithuluzi lokucutshungulwa kwendawo yonke" kanye "nohlelo lokukhiqiza lwesikhathi esizayo izindlela zokucubungula ezijwayelekile".Ubuchwepheshe bokukhiqiza bamazwe ezimboni athuthukile benza ushintsho olusezingeni eliphezulu ngenxa yokusetshenziswa okubanzi kobuchwepheshe bokucubungula i-laser.Ubuchwepheshe bokusika i-laser wukusetshenziswa okuyinhloko kobuchwepheshe be-laser embonini.Isheshise ukuguqulwa kwemboni yokucubungula yendabuko futhi yanikeza izindlela ezintsha zokucutshungulwa kwezimboni zesimanje.Sekuyiyona ndlela esetshenziswa kakhulu kunazo zonke yokucubungula i-laser emkhakheni wokucubungula izimboni, ongathatha yonke imboni yokucubungula i-laser ngaphezu kwama-70%.

Ukusika i-laser ukusetshenziswa kwe-laser high density beam beam egxilile ekhanyisa i-workpiece.Ngaphansi kwesisekelo sokudlula umkhawulo we-laser we-laser power density, amandla e-laser beam kanye negesi esebenzayo esiza inqubo yokusika enamathiselwe ukushisa kwamakhemikhali konke kudonswa yimpahla.Izinga lokushisa lephuzu lesenzo se-laser likhuphuka ngokucijile futhi ngemva kokuba iphuzu lokubilisa selifinyelelwe, impahla iqala ukuhwamuka bese yenza imbobo.Ngokuhamba okuhlobene kwe-light beam kanye ne-workpiece, impahla ekugcineni yakheka ibe yi-slit.Intlenga embotsheni ishaywa igesi ethile esiza.

Ukusika kwe-Laser kunezinzuzo eziningana ezifana nohlu olubanzi lokusika, isivinini sokusika, ukusika okuncane, ikhwalithi enhle yokusika, indawo encane ethintekile ukushisa, kanye nokuguquguquka nokunye.Ubuchwepheshe bokusika i-laser bubuye bube obunye bobuchwepheshe obuvuthwe kakhulu kubuchwepheshe bokucubungula i-laser.Uma kuqhathaniswa nezinye izibani, nazi izici ezilandelayo:

1. Ukukhanya okuphezulu

2. Ukuqondisa okuphezulu

3. I-monochrome ephezulu

4. Ukuhambisana okuphezulu

Futhi ngenxa yalezi zici ezine, isetshenziswe kabanzi, futhi ilethe izici ezibalulekile zokucutshungulwa kwendabuko okulandelayo ekucutshungulweni kwe-laser:

(1) Njengoba kungekho ukucutshungulwa kokuxhumana, futhi amandla e-laser beam nesivinini sokunyakaza kuyalungiseka.Ngakho ungakwazi ukufeza ezihlukahlukene processing.

(2) Ingasetshenziselwa ukucubungula izinhlobonhlobo zezinsimbi, ezingezona ezensimbi.Ikakhulukazi, ingacutshungulwa ubulukhuni obuphezulu, i-brittleness ephezulu kanye nephuzu elincibilikayo lezinto ezibonakalayo.

(3) Awekho "ithuluzi" eligqokwayo ngesikhathi sokucutshungulwa kwe-laser, futhi awekho "amandla okusika" asebenza kucezu lokusebenza.

(4) I-Laser processing yendawo ethintekile yokushisa incane, i-deformation encane ye-workpiece, ukulandelela inani elincane lokucubungula.

(5) I-laser ingacubungula i-workpiece esitsheni esivaliwe ngokusebenzisa i-medium esobala.

(6) I-laser kulula ukuyiqondisa.kungafinyelelwa ngasohlangothini lwenguquko ngokugxila.Kulula kakhulu ukubambisana nohlelo lwe-CNC lokucubungula izingxenye eziyinkimbinkimbi.Ngakho-ke, ukusika kwe-laser kuyindlela yokusika eguquguqukayo kakhulu.

(7) Ukucutshungulwa kwe-laser kunokukhiqiza okuphezulu.Ikhwalithi yokucubungula izinzile futhi ithembekile, izinzuzo ezibalulekile zezomnotho nezenhlalo.

Isikhathi sokuthumela: Jan-04-2021