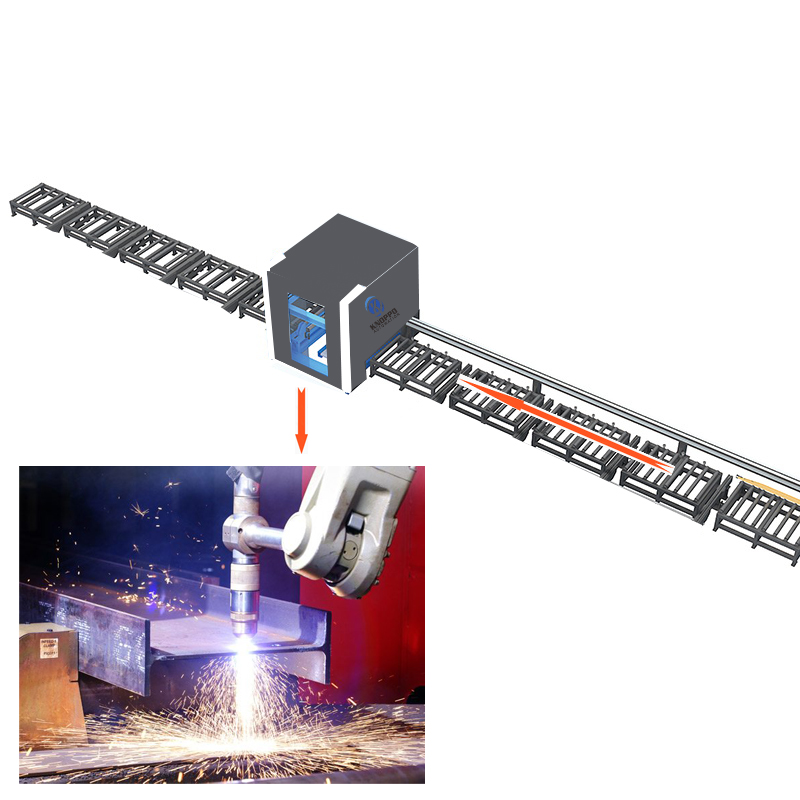

Lo mshini wokusika i-H usetshenziswa kabanzi ekusikeni nasekucubunguleni izingxenye zesakhiwo sepayipi ekwakhiweni, amakhemikhali, ukwakhiwa kwemikhumbi, ubunjiniyela bemishini, i-metallurgy, amandla kagesi nezinye izimboni.Esikhathini esedlule, iningi lalolu hlobo lokucubungula belisebenzisa amasu okusebenza abuyela emuva futhi ayinkimbinkimbi njengokwenza ama-prototypes, ukubhala, ukuphakamisa ama-manual, ukusika ngesandla, nokupholisha ngesandla.Umshini wokusika umugqa ophambanayo we-CNC ungasika futhi ucubungule ama-workpieces anjalo kalula kakhulu.Asikho isidingo sokuthi u-opharetha abale noma ahlele.Udinga kuphela ukufaka i-radius yepayipi, i-angle ye-intersection kanye neminye imingcele yesistimu ye-intersecting yepayipi, futhi umshini ungasika ngokuzenzakalelayo umugqa ophambanayo wepayipi.Izimbobo zomugqa ophambanayo kanye nemisele yokushisela.Umshini wokusika onqamula ipayipi we-CNC usebenzisa ukulawula kwedijithali, kanye nemishini [inombolo yezimbazo zokulawula izimbazo ezimbili kuya kweziyisithupha nezinye izinhlobo ezihlukene.Imodeli ngayinye ibona i-axis yokulawula ehlanganayo ngesikhathi sokusika njengamahora okusebenza, futhi inemisebenzi yokusika imigqa ehlukene ephambanayo kanye nezimbobo eziphambanayo;i-bevel-engeli engaguquki, i-bevel-point-bevel, kanye nemisebenzi yokusika i-bevel-engeli eguquguqukayo;umsebenzi wesinxephezelo sokusika ipayipi

| Indawo yokusebenza | Igama | Amapharamitha |

| Ngiyaqhakaza/Isiteshi Sensimbi/I-Angle steel Beam | 600mm-1500mm | |

| Indlela yokusika | I-Plasma/Flame | |

| Ubude bokusika obusebenzayo | 12m | |

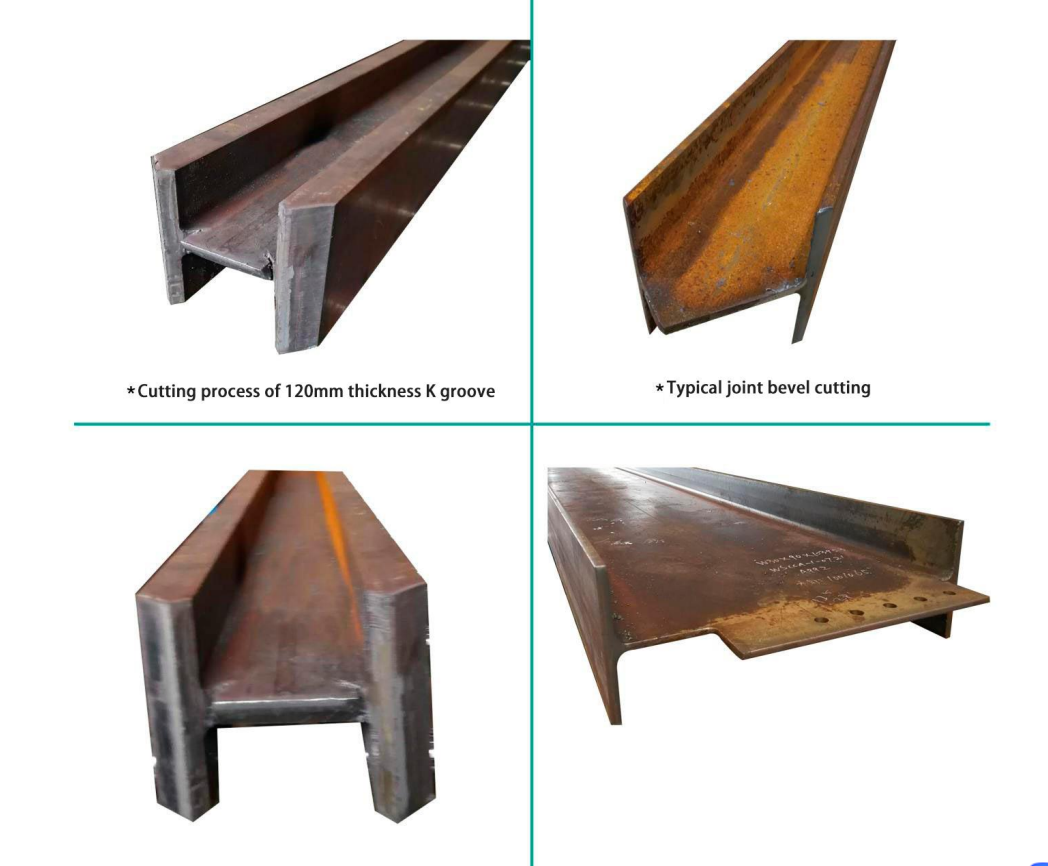

| Iphrofayili yokusika ifomu | Ubude obungaguquki ukusika okuqondile, ukusika okuqondile okuqondile | |

| Izinto ezisetshenziswayo | Insimbi yesakhiwo sekhabhoni, insimbi engagqwali | |

| Ukusika | Umthombo wamandla ePlasma | 200A |

| indlela | Ubukhulu bokusika kwe-plasma | Ukusika kwe-Pierce 1-45mm |

| Oxy fuel cutting ukujiya | Ubukhulu bokusika okuqondile <60mm | |

| Beveling cutting | ±45. | |

| Umshini ukunemba | Ukusika ukunemba ngobude | ±1.5mm |

| Ijubane lokusika | 10 〜2000mm/min | |

| Isivinini esihambayo | 10 〜6000 mm/min | |

| I-eksisi | I-axis yerobhothi | I-X Axis:ukunyakaza kwethoshi lokusika kwesokunxele nakwesokudla |

| I-Y1 Axis&Y2 Axis: I-axis yeqiniso yokuvumelanisa yamazwe amabili : ithoshi elisikayo liya phambili nangemuva | ||

| I-eksisi: ukujikeleza kwethoshi lokusika | ||

| I-axis ye-B: ithoshi lokusika liyazamula | ||

| I-C Axis: i-workpiece yangaphandle ingeyokudla okuvundlile | ||

| I-ZAxis:ithoshi lokusika phezulu naphansi | ||

| Isisindo | Isisindo sephrofayela esiphezulu okufanele sisikwe | 5000kg |

Ividiyo

-

I-Rollerbed Enkulu Ububanzi be-CNC Ipayipi yokusika iBevel...

-

I-5 Axis CNC Square kanye ne-Round Pipe Tube Plasma Cu...

-

I-6 Axis H Beam CNC Cutter Plasma Cutting Coping ...

-

Umshini wokusika iphrofayili ye-Robotic CNC plasma...

-

I-Metal Tube kanye Neshidi le-CNC Plasma Cutter

-

Umugqa wokwenziwa kwe-H beam Automatic H beam cuttin...